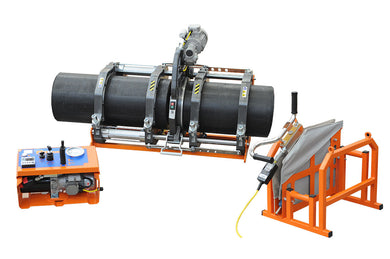

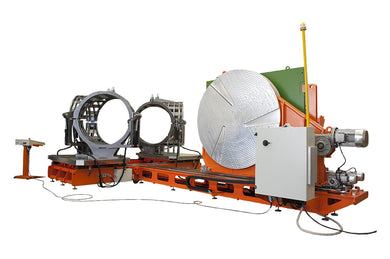

For 20 years Polyweld Machinery has been the trusted supplier for the Plastic Welding Professional.

We are an Australian family-owned and operated company providing complete machinery, tooling, accessories, consumables and hire solutions for thermoplastic welding in every industry and for every application, utilising premium European technology for reliable performance and professional results.